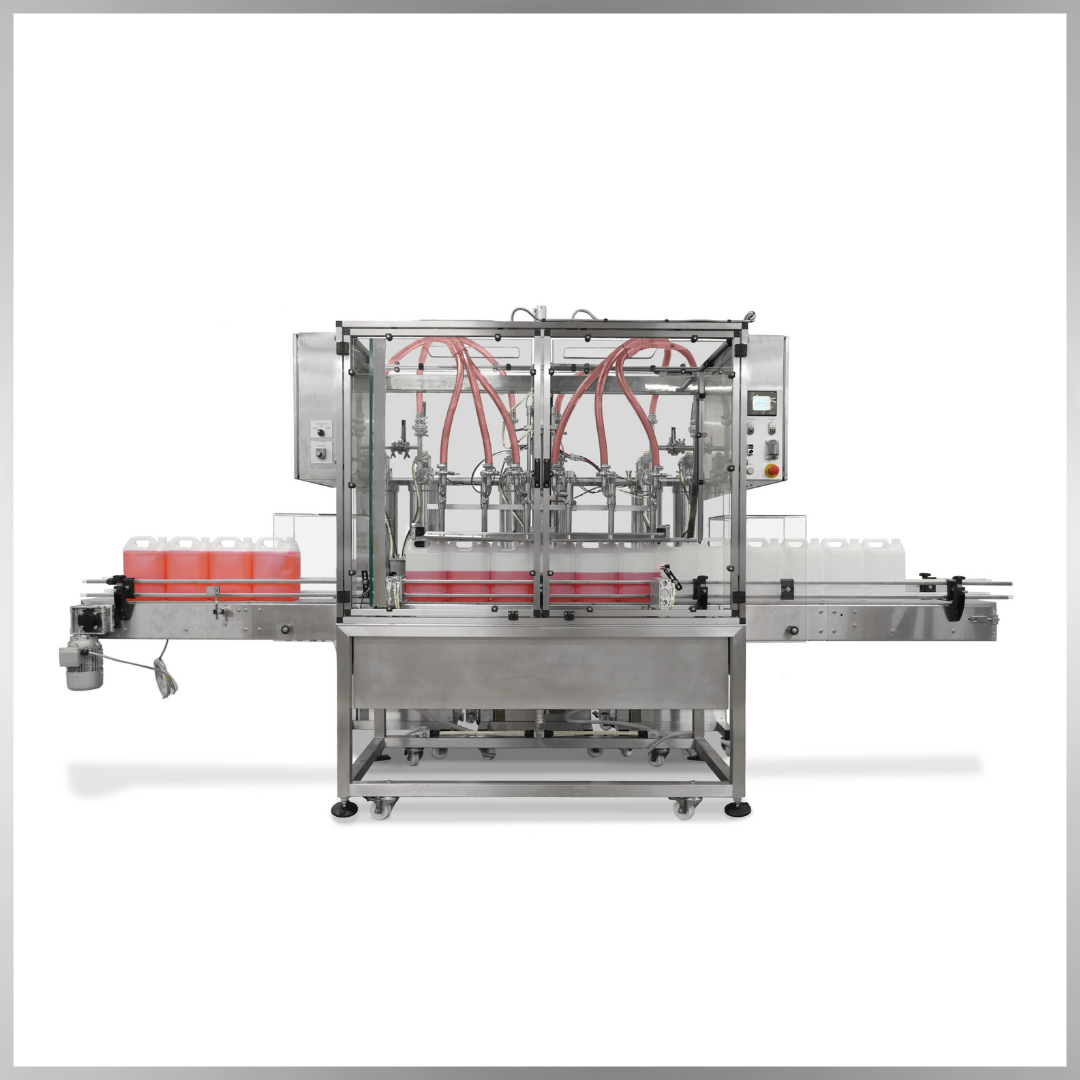

Collar Type - Liquid Filler Machine

The Collar Type – Liquid Filler Machine is a high-performance automatic packaging system designed for efficient filling and sealing of liquid and semi-liquid products. Featuring a collar-type forming system, it converts heat-sealable laminated roll film into pouches, fills them with precise liquid volumes, seals, and cuts them in a fully automated sequence. This ensures hygienic, leak-proof, and consistent packaging across a wide range of applications.

The machine is widely used for water, milk, juices, soft drinks, edible oils, sauces, ketchups, honey, syrups, vinegar, liquid flavorings, cough syrups, tonics, oral solutions, suspensions, disinfectants, hand sanitizers, shampoos, conditioners, lotions, creams, liquid soaps, gels, perfumes, lubricants, paints, cleaning solutions, pesticides, adhesives, chemicals, and inks.

Product Range

Key Features

- Collar-Type Pouch Forming – ensures uniform and elegant pouch shapes.

- Integrated Form-Fill-Seal Operation – film unwinding, pouch forming, liquid filling, sealing, and cutting in one system.

- Accurate Dosing – servo-driven piston or pump ensures precise filling volumes.

- Hygienic & Robust Construction – SS304-grade contact parts for food, pharma, and cosmetic applications.

- Leak-Proof Sealing – pneumatic sealing jaws for strong and consistent seals.

- User-Friendly HMI – PLC-based touch screen interface with recipe storage.

- Versatile Packaging – compatible with low to high viscosity liquids.

- No-Film / No-Fill Safety System – prevents wastage and ensures operational safety

- Quick Changeovers – simple adjustments for different pouch sizes and fill volumes.

- Energy Efficient & Reliable – designed for continuous industrial operation with minimal downtime.

Nitrogen gas flushing unit (for extended shelf life)

Hole punching unit

TTO for batch/date printing

Gusseting unit

Fast-change film roll unit

D-Cut option

Technical Specifications

| Filling Range | 50 ml – 1000 ml (extendable up to 5 liters on request) |

| Output Speed | 30 – 70 pouches per minute (depending on product viscosity & pouch size) |

| Film Type | Heat-sealable laminated films (PET/PE, BOPP, Aluminum foil laminates, etc.) |

| Film Roll Width | 200 mm – 420 mm (customizable) |

| Pouch Formats | Pillow pouch, gusseted pouch, and center-seal pouch options |

| Sealing System | Pneumatic/servo-controlled horizontal & vertical sealing jaws |

| Filling System | Servo-driven piston/volumetric pump system for accuracy |

| Tank Capacity | 30–50 liters with optical level sensor for auto-refill |

| Material of Construction | SS304 contact parts, SS202/MS with powder coating for non-contact parts |

| Power Requirement | 3 Phase, 415 VAC, 50 Hz |

| Compressed Air Requirement | 2 HP, 6–8 Bar pressure |

| Machine Dimensions | Approx. 1.2 m (W) × 2.3 m (H) × 1.6 m (L) |

| Weight | 600–750 kg |