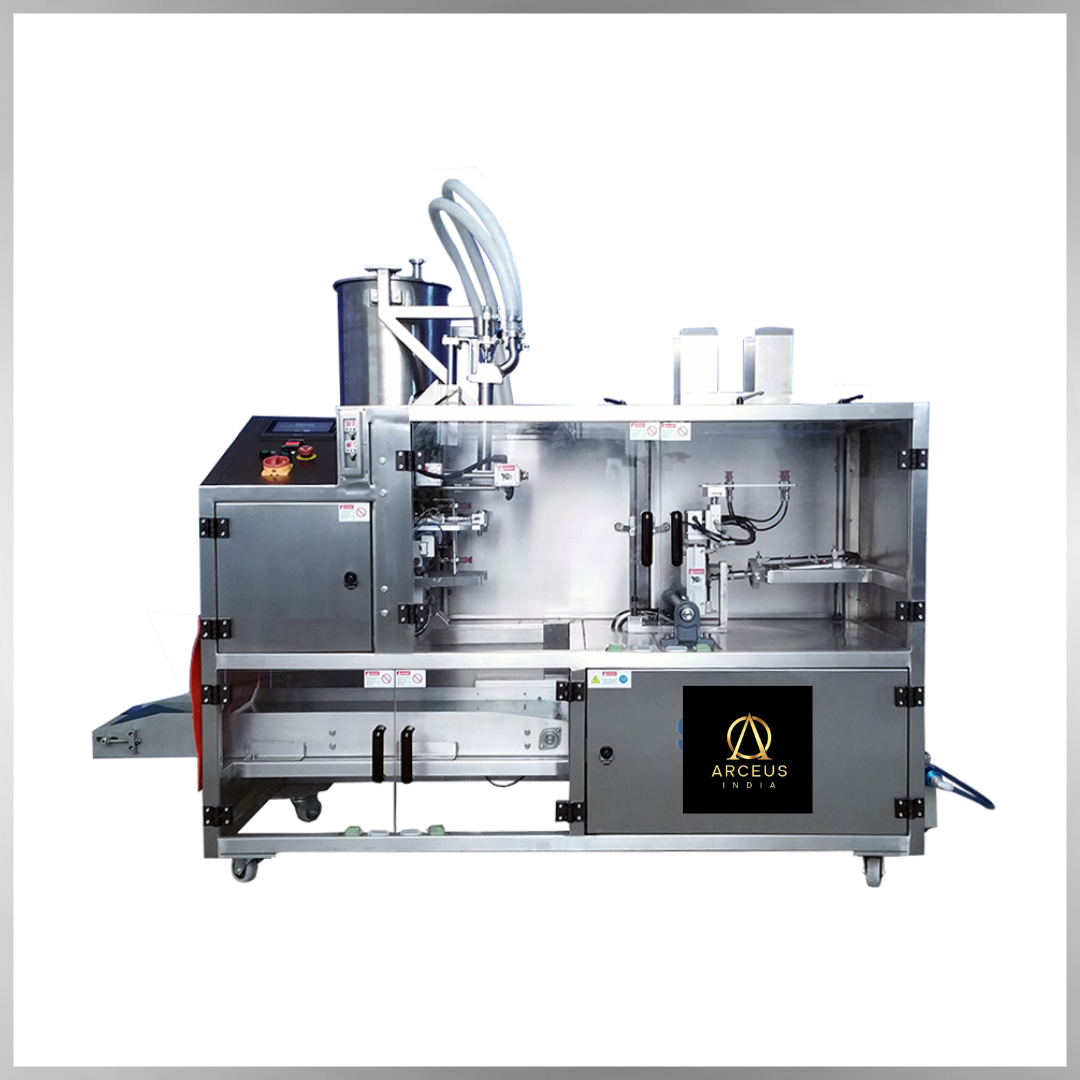

Pick Fill & Seal Machine

The Pick Fill and Seal (PFS) Machine is a versatile, fully automatic packaging solution designed for pre-formed pouches. With advanced rotary indexing technology, the machine picks up empty pouches, fills them with precise quantities of product, and seals them securely. This ensures hygienic, efficient, and tamper-proof packaging across food, pharmaceutical, cosmetic, and industrial applications.

The Pick Fill and Seal Machine is widely used for packing Namkeen, Chips, Dry Fruits, Frozen Foods, Spices, Rice, Pulses, Grains, Sugar, Flour, Tea, Coffee, Bakery Mixes, Sauces, Pastes, Ketchup, Honey, Mayonnaise, Ready-to-Eat Meals, Milk Powder, Ghee, Butter, Cheese, Curd, Milkshakes, Energy Drinks, Flavored Powders, Protein Powders, Health Drink Mixes, Tablets, Capsules, Ayurvedic Powders, Oral Rehydration Salts, Supplements, Shampoos, Creams, Gels, Lotions, Talcum Powders, Face Masks, Scrubs, Detergents, Fertilizers, Pesticides, Seeds, Industrial Powders, Adhesives, Lubricants, Dog Food, Cat Food, Fish Feed, and Bird Feed.

Product Range

Key Features

- Fully Automatic Pick-Fill-Seal Process – ensures consistent and hygienic pouch packaging.

- Flexible Pouch Handling – compatible with multiple pouch types and sizes.

- High Accuracy Filling – integrates with weighers, augers, piston fillers, and volumetric systems.

- PLC & HMI Control System – intuitive interface for easy operation and monitoring.

- Quick Changeover Design – allows switching between different pouch sizes and products.

- Hygienic Build – SS304 contact parts meet international food & pharma safety standards.

- Multi-Product Versatility – suitable for powders, granules, liquids, semi-liquids, and pastes.

- Integrated Safety Features – pouch detection sensors and auto-stop for fault conditions

- Customizable Stations – 4 to 8 station options for higher productivity.

Nitrogen gas flushing unit (for extended shelf life)

Hole punching unit

TTO for batch/date printing

Gusseting unit

Fast-change film roll unit

D-Cut option

Technical Specifications

| Model Options | 4-Station / 6-Station / 8-Station Rotary PFS Machine |

| Pouch Formats Supported | Stand-up pouch, zipper pouch, spout pouch, gusset pouch, flat pouch |

| Pouch Size Range | Width – 80 mm to 300 mm; Length – 100 mm to 400 mm (customizable) |

| Filling Systems Compatible | Multihead weigher, auger filler, cup filler, liquid piston filler |

| Filling Capacity | 10 g to 5 kg (product dependent) |

| Output Speed | 30–60 pouches per minute (based on product and filling system) |

| Sealing Type | Heat sealing with pneumatic control |

| Control System | PLC-based with HMI touchscreen |

| Power Requirement | 3 Phase, 415 V AC, 50 Hz |

| Air Requirement | 6–8 Bar, 3–5 CFM |

| Construction | SS304 contact parts, MS/SS body with powder coating |

| Safety | Pouch detection sensor, no-pouch–no-fill mechanism, overload protection |