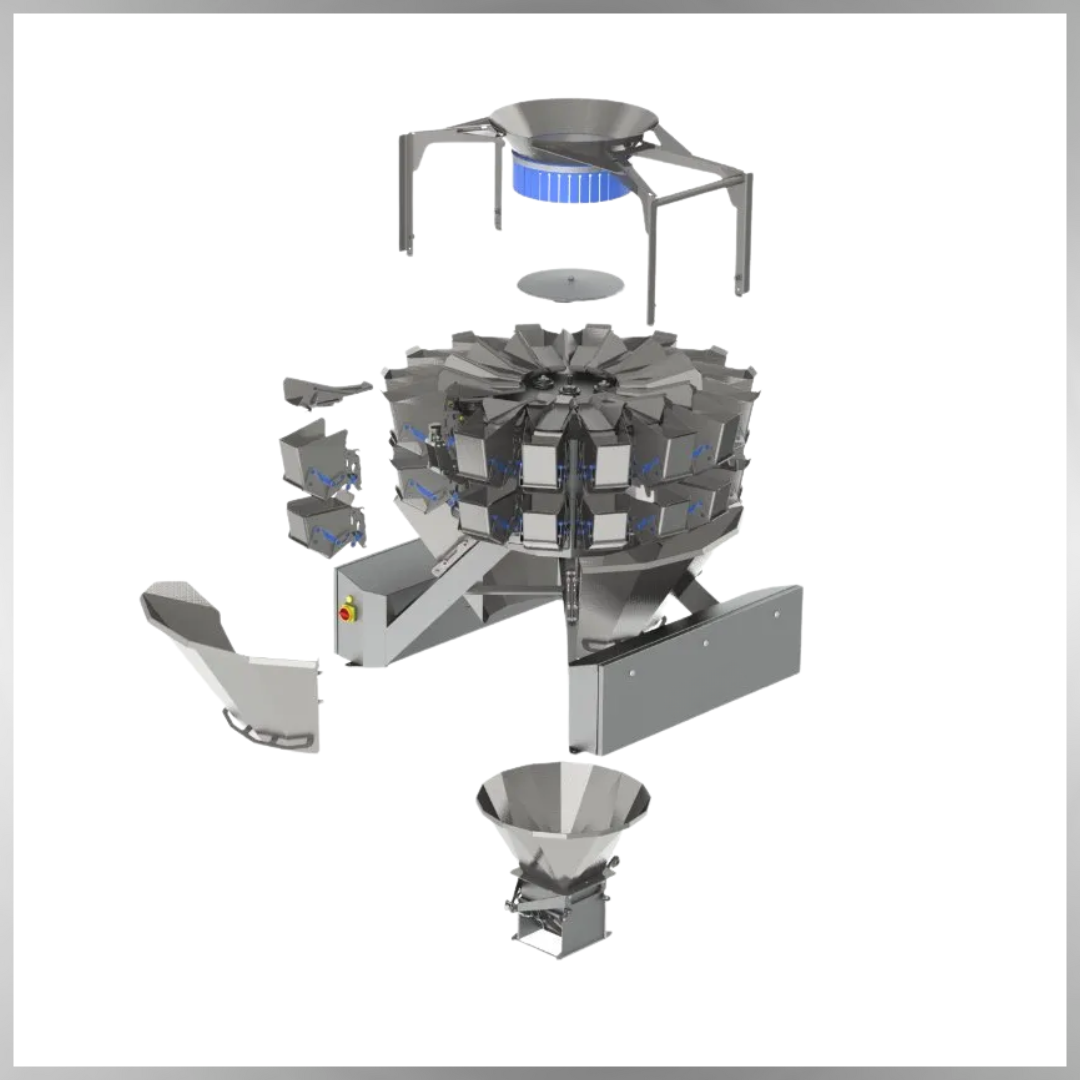

10 Head Weigh Filler Machine

The 10 Head Multihead Weigher Machine is designed for high-speed, high-accuracy pouch packing, making it an essential solution for large-scale production environments. Operating at 45– 60 packs per minute, this machine uses advanced combination dumping technology to deliver both precision and efficiency.

Whether you need a Chips Packing Machine, Namkeen Packing Machine, Wafers Packing Machine, Makhana Packing Machine, Popcorn Packing Machine, or Frozen Food Packing Machine (peas, nuggets, fries, prawns, shrimps), This system ensures consistency and reliability for every pack. It is equally effective for Nuts, Dry Fruits, Pulses/Dals, Grains, Tea, Coffee Beans, Poha/Puffed Rice, Confectionery, Mix Farsan, Peeled Garlic, Pet Food, and even Small Hardware Items like screws, washers, and dowel pins.

This Made in India multihead pouch packing machine is equipped with a robust microcontroller-based system, HMI touch screen, and an automated sensor-driven mechanism to reduce material wastage and ensure leak-proof packaging.

Product Range

Optional Accessories

- Nitrogen gas flushing unit (for extended shelf life)

- Hole punching unit

- TTO for batch/date printing

- Gusseting unit

- Fast-change film roll unit

- D-Cut option

Key Features

- Made in India – designed, developed, and manufactured in-house

- Large HMI touch screen with indigenous software

- Motorized pulling system for smooth film handling

- Microcontroller-based system for precise operations/li>

- Strip or individual count cutting provided

- Works on single phase power supply

- All electronic control instruments manufactured in-house

Nitrogen gas flushing unit (for extended shelf life)

Hole punching unit

TTO for batch/date printing

Gusseting unit

Fast-change film roll unit

D-Cut option

Technical Specifications

| Items to be Packed | Granular, Fluffy, Irregular shaped, Solids |

| Max Capacity | 5g- 1kg |

| Accuracy | 0.1 – 1.5 gms |

| Max Speed | 45-60 pouches per minutes* |

| Pouch width | 50-250 mm |

| Pouch length | 65 – 330 mm |

| Film Width | 120 -530 mm |

| Power requirement | 2KW, Single phase 230 VAC |

| Material Construction | All contact parts SS304, & other parts of MS |

| Air Requirement | 2HP,8Bar Pressure.2 CFM |

| Forming type | Collar |

| Horizontal seal width (mm) | 10/15 typical |

| no of weighing Pan | 10no |

| Dimension (W x H xD) in ft. | 7 x 11 x 6 (without Conveyor). |

| Serration and cutting | Count cutting provided, count to be fed through |

| Control of FFS | Through micro controller |

| Eye mark controller | Provided. |

| Process parameter setting | Through HMI. |

| Film draw mechanism | Through steeper/ servo motor |

| Horizontal sealing mechanism | Pneumatic |

| Vertical seal mechanism | Pneumatic |