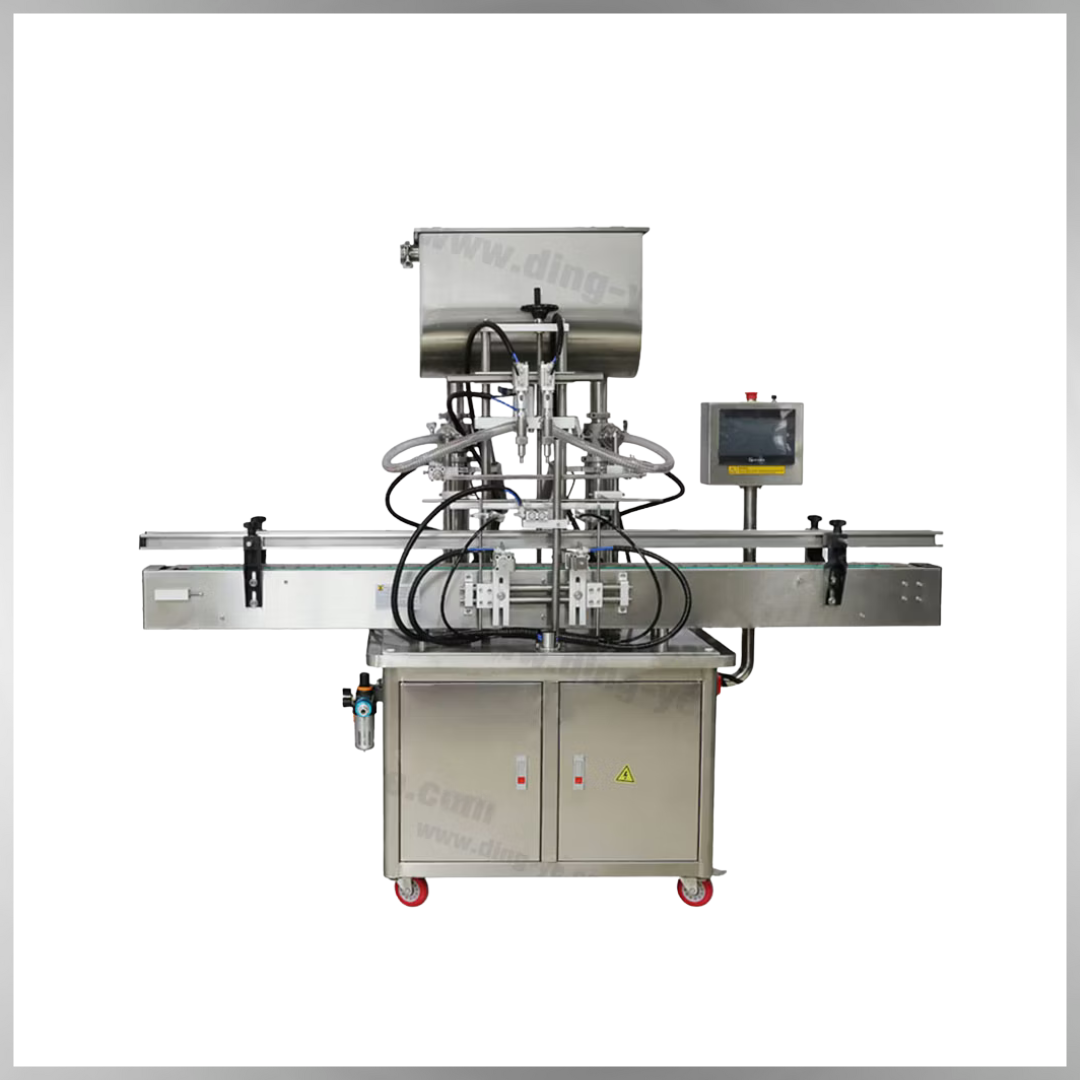

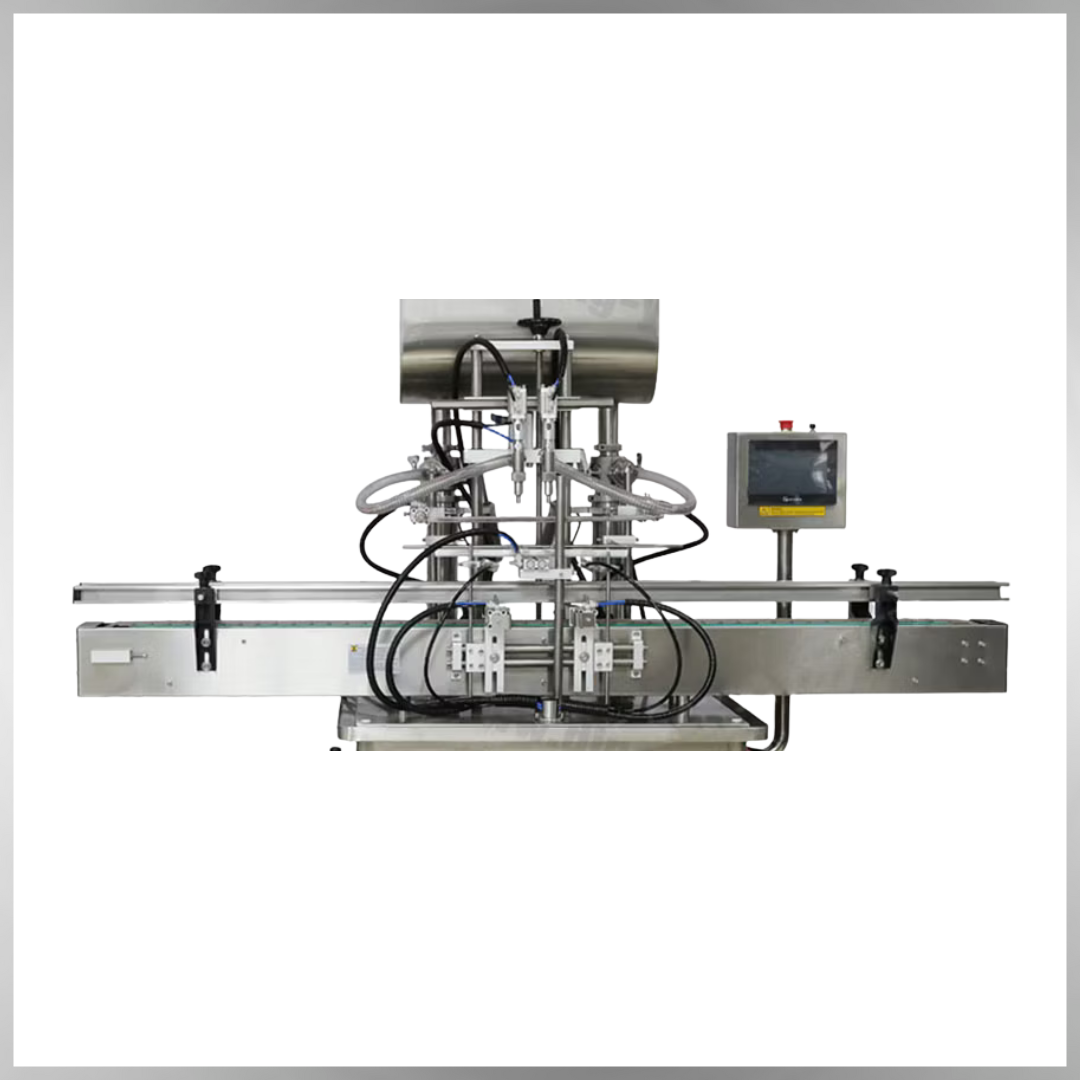

Former Type - Paste Filler Machine

The Former Type – Paste Filler Machine is a fully automatic, high-performance packaging solution designed for filling and sealing viscous and semi-viscous products with superior accuracy and hygiene. Built with a robust stainless-steel frame and SS304-grade contact parts, it ensures compliance with food, pharmaceutical, cosmetic, and industrial standards.

It is widely used for jams, sauces, ketchup, honey, peanut butter, syrups, mayonnaise, chutneys, pastes, ghee, condensed milk, edible oils, creams, lotions, gels, shampoos, conditioners, serums, toothpaste, cosmetic pastes, ointments, balms, medicinal syrups, viscous suspensions, adhesives, lubricants, resins, waxes, greases, detergents, and industrial pastes.

Product Range

Key Features

- High-Precision Paste Filling – double-piston pneumatic system ensures accurate dosing.

- Former-Type Pouch Forming System – creates uniform, strong, and leak-proof pouches.

- Stainless-Steel Hygiene – SS304 contact parts for food, pharma, and cosmetic applications.

- Advanced PLC & HMI – user-friendly 7-inch touchscreen for control, settings, and diagnostics.

- Reliable Sealing Mechanism – pneumatic vertical and horizontal sealing for consistent pouch integrity.

- Wide Packaging Flexibility – supports 220–420 mm roll width for multiple pouch sizes.

- Photo-Eye Registration – Panasonic photocells ensure precise film alignment.

- Optical Tank Sensor – automatic monitoring prevents overfill/underfill issues.

- Heavy-Duty Construction – engineered for 24×7 operations with minimal maintenance.

- Multi-Industry Versatility – suitable for food, beverages, cosmetics, pharmaceuticals, chemicals, and industrial pastes.

Nitrogen gas flushing unit (for extended shelf life)

Hole punching unit

TTO for batch/date printing

Gusseting unit

Fast-change film roll unit

D-Cut option

Technical Specifications

| Model | Former Type – Paste Filler |

| Filling Range | 500 g – 1000 g |

| Tank Capacity | 30 kg with optical level sensor |

| Filling System | Double piston filler with pneumatic drive |

| Film Roll Width | 220 mm – 420 mm |

| Output Speed | 15–20 fills/min (for 500 g) 10–12 fills/min (for 1 kg) |

| Control System | PLC-based (Innovance/Delta) with Omron/NHP SMPS |

| Display | 7-inch HMI touchscreen |

| Drive System | Induction motor with belt pulling, DC motor for film unwinding |

| Sealing Operations | Pneumatic vertical & horizontal sealing, batch cutting, paste filling |

| Pneumatic Accessories | Janatics (India) |

| Photocell Sensors | Panasonic (for accurate film registration) |

| Temperature Controllers | Selec/Multispan make |

| Electrical Accessories | Schneider, L&T, Polycab wiring |

| Material of Construction |

Contact Parts: SS 304 (food-grade) Non-Contact Parts: SS 202 with cladding |

| Safety System | Optical sensor for tank monitoring |

| Power Requirement | 3 Phase, 415 VAC |

| Air Requirement | 2 HP, 6–8 bar |