Trishula Robotic Solutions Pvt Ltd is revolutionizing visual inspection with cutting-edge remote and robotic technologies designed to navigate challenging industrial environments efficiently. Our solutions enhance safety, accuracy, and efficiency, minimizing downtime while ensuring comprehensive asset integrity assessment.

- Email: inspection@trishularobotics.com

ADVANCED REMOTE VISUAL INSPECTION

Cutting-Edge Solutions for Challenging Environments

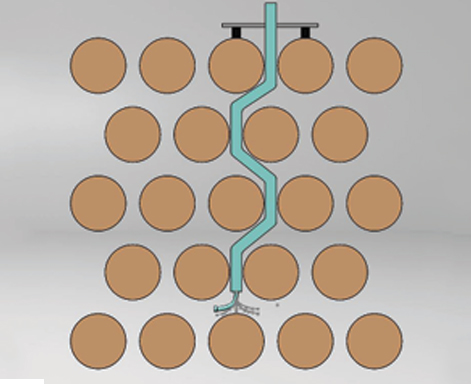

SNAKE-EYE SYSTEM

Advanced Inspection of Heater Convection Coils

The SNAKE-EYE system is designed for inspecting complex heater convection coils with a triangular pitch arrangement, overcoming traditional accessibility challenges.

Key Benefits:

- Unique Probe Design – Maneuvers through tight zig-zag gaps for complete external tube inspection.

- Enhanced Throughput & Reliability – Improves inspection efficiency without compromising uptime.

- Minimal Downtime – Eliminates the need for elbow cutting and convection box opening.

- Increased Safety – Reduces reliance on hot work permits and manual intervention.

- 100% Tube Coverage – Provides permanent inspection records for in-depth analysis.

- Defect Detection – Accurately identifies erosion, corrosion, leaks, and fin/stud damage.

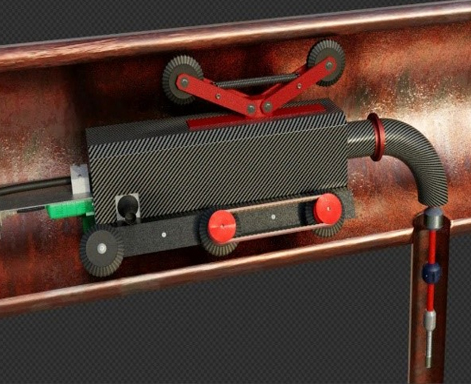

ARBOR TUBE INSPECTION

Robotic Crawler for Confined Space-Free Inspections

Trishula Robotic Solutions introduces an innovative robotic crawler for Arbor tube inspection, eliminating manual confined space entry.

Key Benefits:

- Unrestricted Header Access – Freely navigates within headers, inspecting every tube.

- 360° Articulating Head – Enables precise camera deployment at any angle.

- Extended Reach – Covers up to 20 meters in both upward and downward directions.

- Confined Space-Free Inspection – Eliminates safety hazards of manual entry.

- Expedited Inspection Process – Reduces downtime with an efficient scanning mechanism.

- Unlimited Track Length – Adapts to headers of any size for flexible deployment.

UV LIGHT INSPECTION IN OXYGEN PLANTS & PIPELINES

Ensuring Contaminant-Free Operations

Our UV-based inspection system is an industry-first solution for detecting oil and hydrocarbon contamination in oxygen pipelines. The system is designed for both crawler-based and manual camera applications.

Advantages:

- Enhanced Detection – UV lights specifically target oil and hydrocarbon residues.

- Versatile Deployment – Available in both robotic crawler and manual configurations.

- Proactive Maintenance – Enables early contamination detection, preventing catastrophic failures.

- Increased Safety – Reduces the risk of oxygen pipeline hazards.

- Reliable Data Collection – Generates detailed contamination reports for corrective action.

WIND TURBINE BLADE INSPECTION

Maximizing Renewable Energy Efficiency

Wind turbine blades play a crucial role in renewable energy generation. Our HD Pan-Tilt Zoom camera systems provide a comprehensive internal blade inspection, ensuring optimal performance and longevity.

Key Benefits:

- Comprehensive Assessment – Thoroughly examines the blade’s internal components for early defect detection.

- Minimized Risk – Eliminates manual entry risks, enhancing personnel safety.

- Optimized Efficiency – Reduces downtime by streamlining the inspection process.

- High-Accuracy Data Collection – Captures high-resolution images & videos for detailed reporting.

INNOVATION & TECHNOLOGY

Our in-house R&D department continuously develops specialized inspection solutions, pushing the boundaries of automation, robotics, and non-destructive evaluation to serve varied industrial applications.