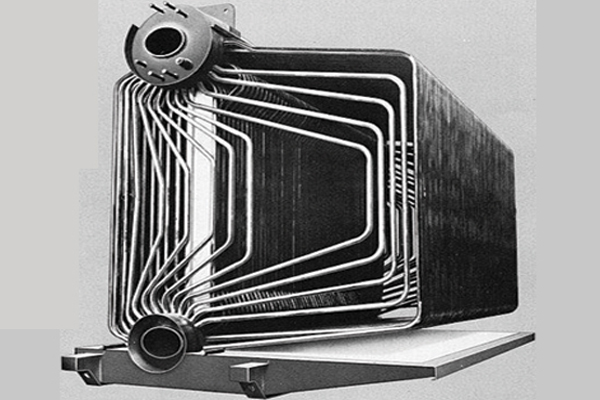

Boiler tube inspection behind swage reductions has always posed a challenge for inspectors. Traditional inspection methods relying on fixed-diameter probes often suffer from low fill-factor, poor sensitivity, and limited defect resolution, making them unreliable for detecting critical flaws.

At Trishula Robotic Solutions Pvt Ltd, we provide a comprehensive and advanced inspection solution using TFET (Transition Field Electromagnetic Technique). Our ID FLEX ARRAY PROBE is specifically designed to overcome these limitations, ensuring full-length, high-resolution, and high-sensitivity inspections for both swage and non-swage boiler tubes.