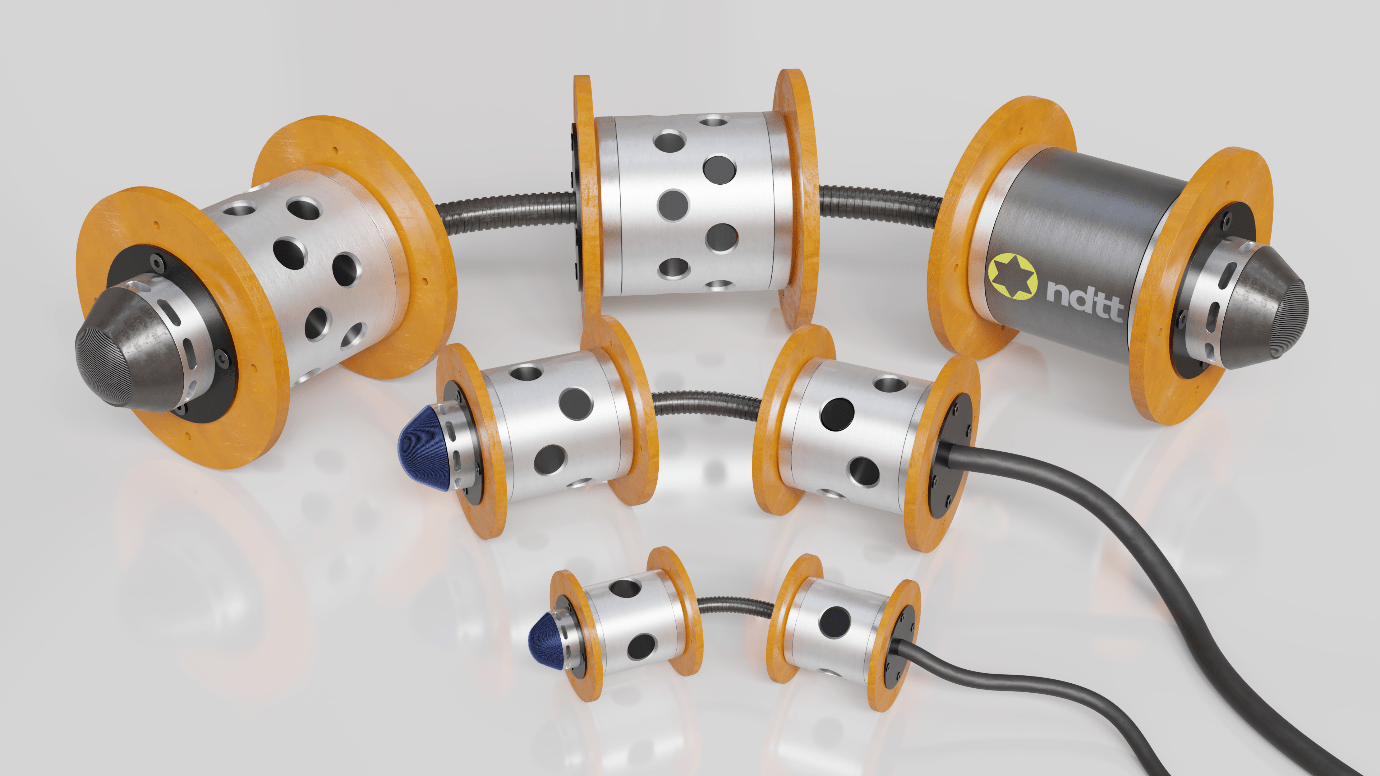

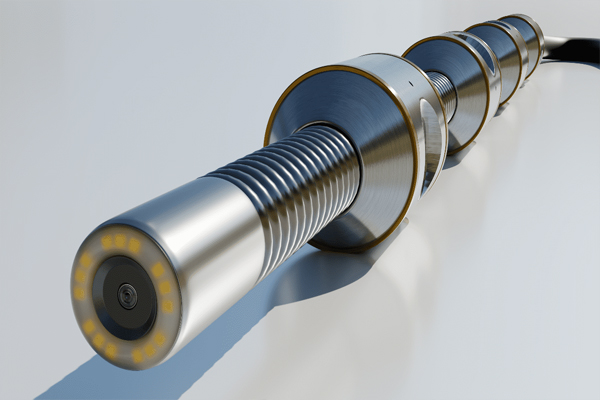

Maintaining pipeline integrity is critical, especially for small-diameter lines (30mm to 100mm)...

Our Tethered Pigging Technology overcomes these challenges by providing a controlled, high-precision inspection solution that ensures early anomaly detection, minimal downtime, and extended pipeline life.