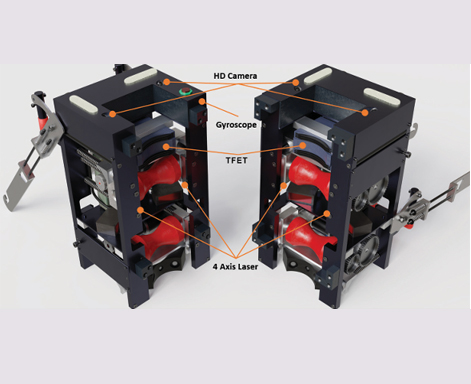

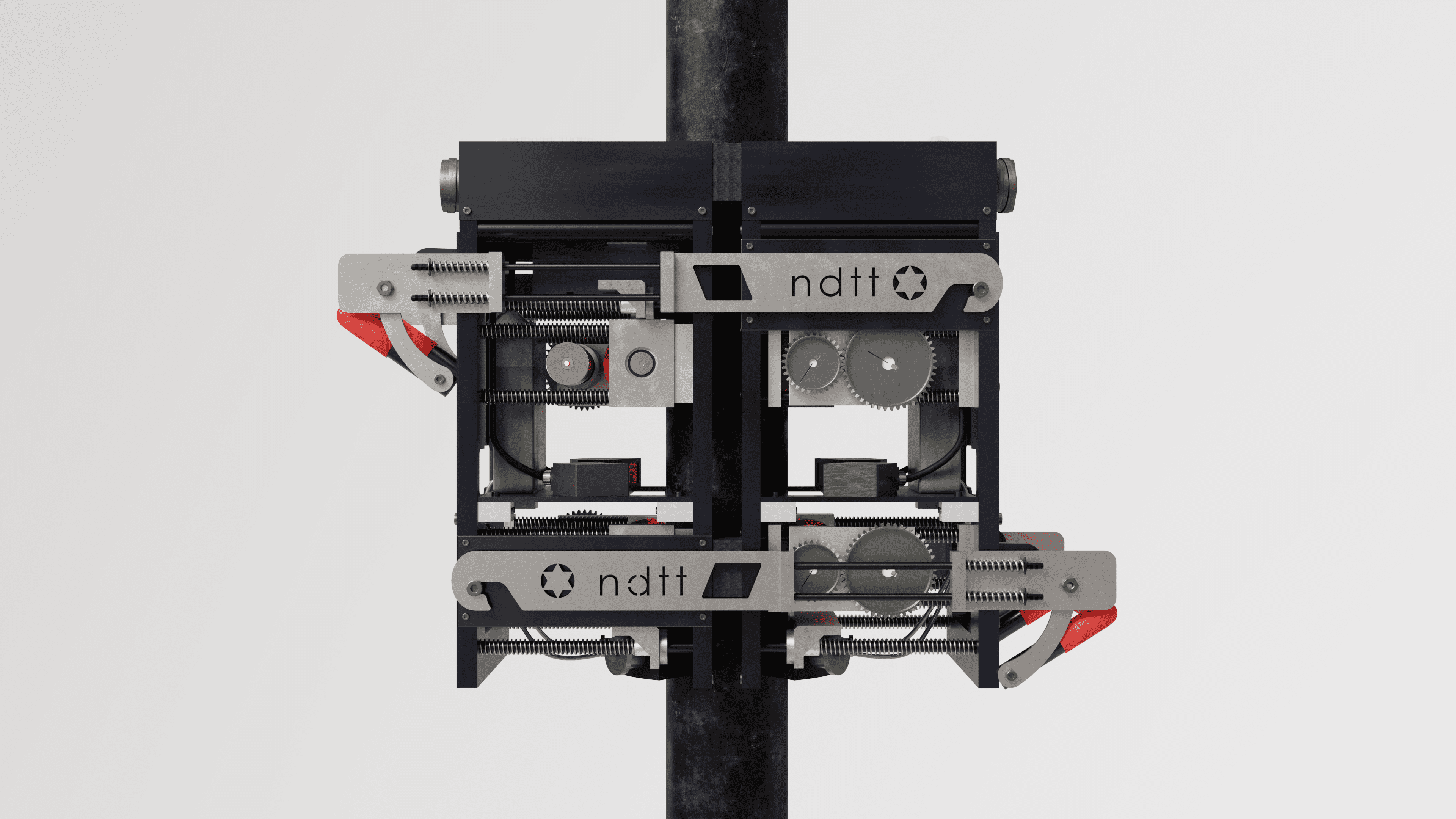

reF-SCAN is an advanced, indigenously developed robotic inspection system that sets a new benchmark in reformer tube evaluation. Utilizing a combination of Transition Field Electromagnetic Technique (TFET), high-precision laser scanning, gyroscope measurements, and HD imaging, it delivers the most comprehensive assessment of reformer tubes available today.

- Email: inspection@trishularobotics.com

REFORMER TUBE INSPECTION – reF-SCAN

REFORMER TUBE INSPECTION – reF-SCAN

Why Choose reF-SCAN?

- Comprehensive Multi-Technology Approach – Combines multiple inspection methods in a single scan.

- Fast & Reliable Data Acquisition – Minimizes downtime and enhances operational efficiency.

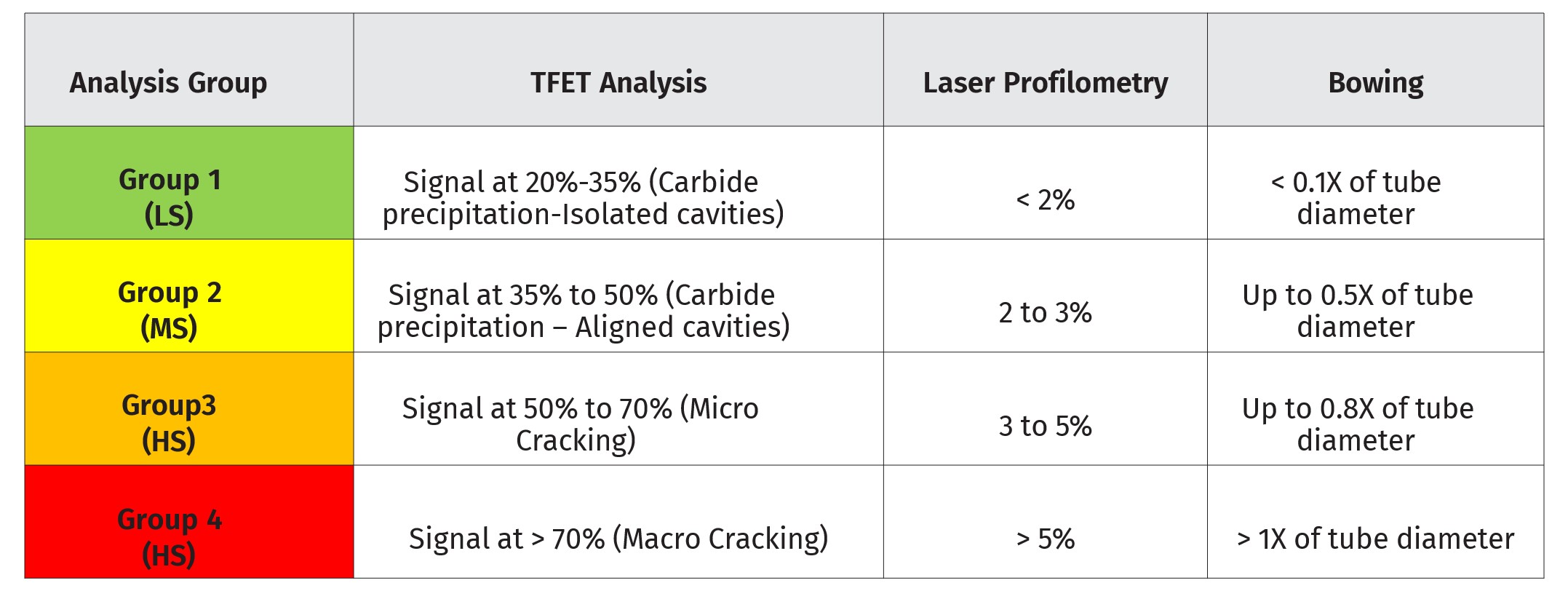

- Accurate Microstructural Analysis – Directly correlates TFET signals to carburization and creep damage.

- Actionable Insights for Maintenance – Helps schedule preventive replacements before failures occur.

Key Technologies & Capabilities

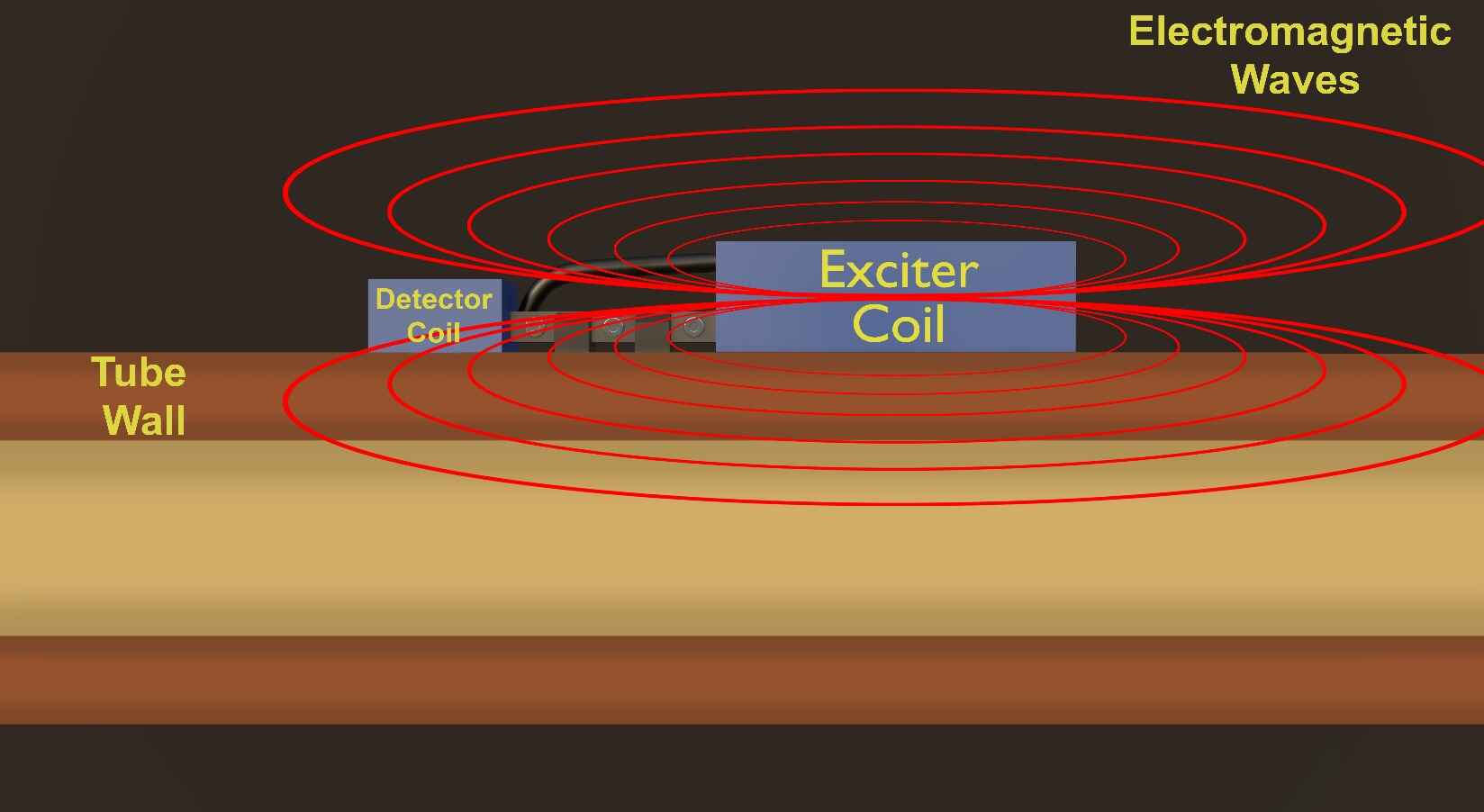

- TFET – A Breakthrough in Creep

and Carburization Analysis

- Deep Penetration – Scans up to 25mm into the tube wall, detecting early-stage microstructural degradation.

- Minimal Cleaning Required – Eliminates the need for extensive tube preparation.

- Material & Defect Agnostic – Effective on ferrous, non-ferrous, and centrifugally cast tubes, detecting both ID & OD defects.

- 4-Axis Laser – High-Precision OD Measurement – Measures OD variations to identify creep, bulging, and wall thinning.

- Gyroscope – Accurate Tube Bowing Detection – Detects even the slightest deviations in tube shape.

- HD Cameras – Visual Inspection – Captures high-resolution imagery for corrosion and surface defect analysis.

- Pigtail Inspection – Dedicated TFET probe for targeted pigtail integrity assessment.

Remaining Life Assessment – reF-Life

Understanding the remaining life of reformer tubes is critical for optimizing maintenance strategies. reF-SCAN goes beyond inspection—it integrates with reF-Life, an advanced API 579-1/ASME FFS-1 compliant software, to provide:

- Data-Driven Tube Life Predictions – Analyzes operational conditions, inspection data, and degradation patterns.

- Carbide Build-Up Detection – TFET’s unparalleled sensitivity helps directly measure microstructural damage.

- Accurate Remaining Life Estimations – Supports proactive maintenance planning and failure prevention.

Maximize Efficiency, Minimize Risk

With reF-SCAN and reF-Life, operators gain a holistic view of reformer tube health, enabling data-driven decisions that enhance safety, extend equipment lifespan, and improve overall plant performance.