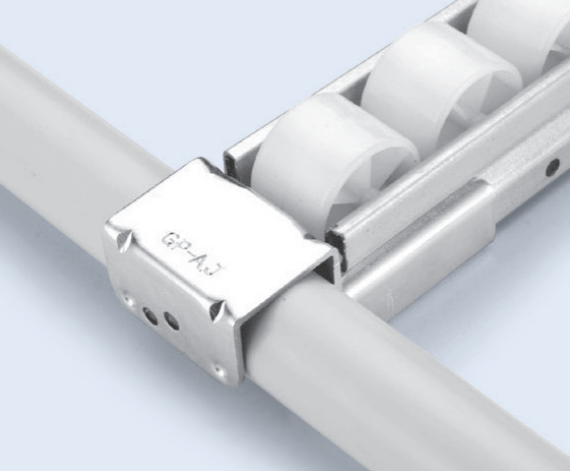

GPA

Coated pipes are specially treated with protective layers to enhance their durability, resistance to corrosion, and overall lifespan. These coatings can be applied externally, internally, or both, depending on the intended use and environmental exposure. Typically used in industries like oil and gas, water treatment, and construction, coated pipes provide an extra barrier against harsh chemicals, moisture, and physical wear. The coating not only prevents rust and corrosion but also minimizes friction in flow applications, making them ideal for transporting fluids. With proper coating, these pipes maintain structural integrity over long periods, even in extreme conditions, reducing maintenance needs and improving system efficiency.

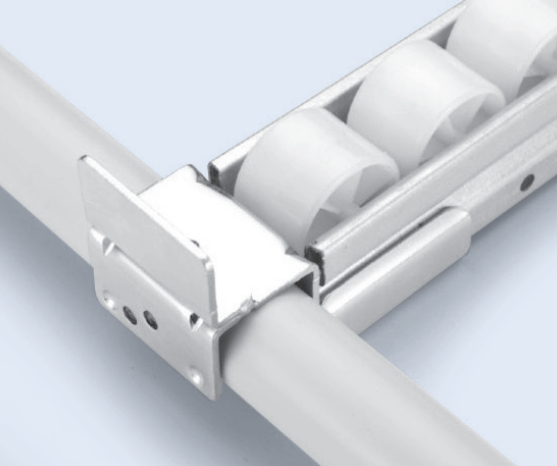

GPB

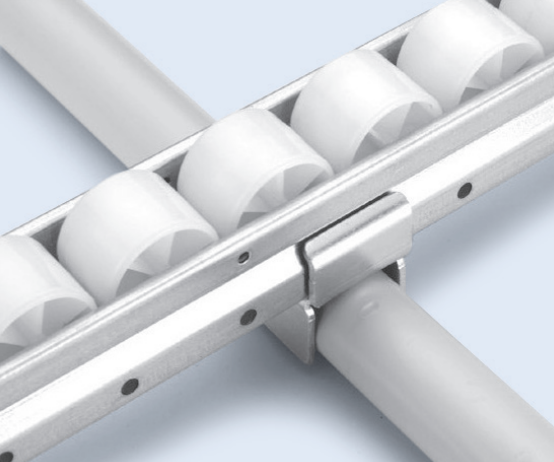

Powder coated pipes are steel or metal pipes that have undergone an advanced finishing process where dry powder is electrostatically applied and then cured under heat to form a tough, smooth, and uniform protective layer. This coating offers excellent resistance to corrosion, UV exposure, chipping, and scratches, making it highly suitable for both indoor and outdoor applications. Commonly used in modular pipe structures, racking systems, and cleanroom environments, powder coated pipes are also preferred for their aesthetic appeal, available in various colors and finishes. Their environmentally friendly application process, which emits no VOCs (Volatile Organic Compounds), further adds to their popularity across industries seeking sustainable and durable solutions.

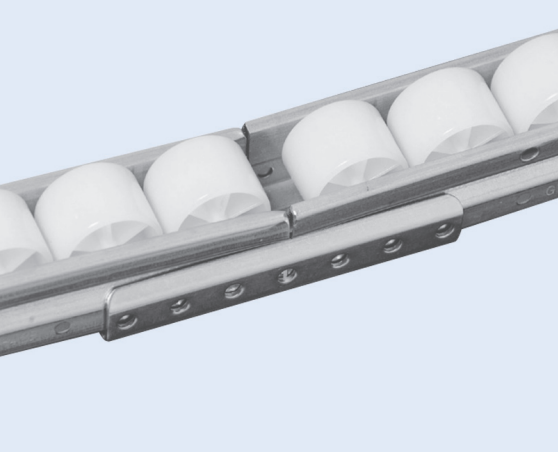

GPC

Coated pipes are specially treated with protective layers to enhance their durability, resistance to corrosion, and overall lifespan. These coatings can be applied externally, internally, or both, depending on the intended use and environmental exposure. Typically used in industries like oil and gas, water treatment, and construction, coated pipes provide an extra barrier against harsh chemicals, moisture, and physical wear. The coating not only prevents rust and corrosion but also minimizes friction in flow applications, making them ideal for transporting fluids. With proper coating, these pipes maintain structural integrity over long periods, even in extreme conditions, reducing maintenance needs and improving system efficiency.

GPC1

Powder coated pipes are steel or metal pipes that have undergone an advanced finishing process where dry powder is electrostatically applied and then cured under heat to form a tough, smooth, and uniform protective layer. This coating offers excellent resistance to corrosion, UV exposure, chipping, and scratches, making it highly suitable for both indoor and outdoor applications. Commonly used in modular pipe structures, racking systems, and cleanroom environments, powder coated pipes are also preferred for their aesthetic appeal, available in various colors and finishes. Their environmentally friendly application process, which emits no VOCs (Volatile Organic Compounds), further adds to their popularity across industries seeking sustainable and durable solutions.

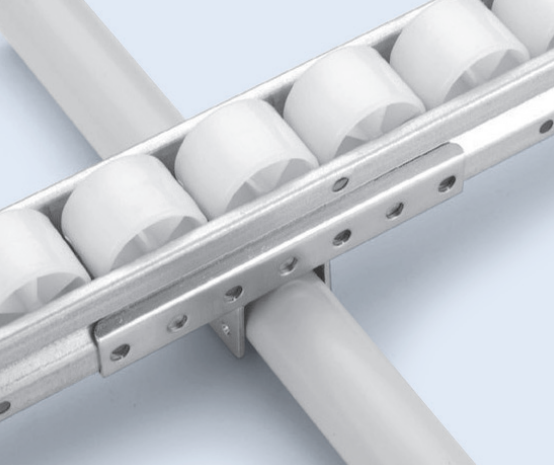

GPE

Coated pipes are specially treated with protective layers to enhance their durability, resistance to corrosion, and overall lifespan. These coatings can be applied externally, internally, or both, depending on the intended use and environmental exposure. Typically used in industries like oil and gas, water treatment, and construction, coated pipes provide an extra barrier against harsh chemicals, moisture, and physical wear. The coating not only prevents rust and corrosion but also minimizes friction in flow applications, making them ideal for transporting fluids. With proper coating, these pipes maintain structural integrity over long periods, even in extreme conditions, reducing maintenance needs and improving system efficiency.